भाकृअनुप - केन्द्रीय कृषि अभियांत्रिकी संस्थान, भोपाल

ICAR - Central Institute of Agricultural Engineering, Bhopal

Energy in agriculture and agro-based industries

About AICRP

The ICAR-AICRP on Energy in Agriculture and Agro-based Industries (EAAI) was launched in 1983 initially with 13 cooperating centres with its name as AICRP on Renewable Source of Energy (RES) for Agriculture and Agro based Industries. The name of the project was revised as (ICAR-AICRP on EAAI) with effect from 2015-16. Initially this project was initiated by combining two earlier projects, one on Solar Energy Utilization and another on Biogas technology, which were operating since 1977. Over the period, scope of the project was broaden and name and mandate of the project was revised as ICAR-AICRP on EAAI. Now this project contains three different components, namely Development of Renewable Energy Technologies (DRET), Energy Management in Agriculture (EMA) and Demonstration of Renewable Energy Systems (DRES). The R & D component of the Project (DRET) was further bifurcated into four sub-components namely DRET-SET (DRET- Solar Energy Technology), DRET-BCT (DRET-Bio-chemical Conversion Technology), DRET-TCT (Thermo-chemical Conversion Technology) and DRET-LBT (DRET-Liquid Bio-fuel Technology).

Mandate/Major programme/Mission

The approved mandate of the Project includes development of technologies and processes for enhanced use efficiency of renewable and non-renewable energy sources in production agriculture and agro-processing.

Objectives/Thrust Area

Development and demonstration of technologies and practices for enhancing utilization efficiency of conventional energy based systems and augmenting use of renewable energy in agricultural sector.

Contact Us

Dr. V.K. Bhargava

Project Coordinator, AICRP on EAAIICAR-Central Institute of Agricultural Engineering,

Nabibagh, Berasia Road, Bhopal – 462 038

Phone: 0755-2747431

Fax: 0755-2747431

Email: Vinod.Bhargav@icar.gov.in

List of centres

| S. No. | Name of Centre | Principal Investigator Location | Phone,

Fax No., E-mail address |

Activity | ||

|---|---|---|---|---|---|---|

| R&D | PMW | PFT/FLD | ||||

| 1. | PDKV Akola | Dr. A.K. Kamble Research Engineer, AICRP on EAAI, Department of Renewable Energy Sources & Other Electrical Engineering, Dr. Punjabrao Deshmukh Krishi Vidyapeeth, Post Office – Krishinagar, Akola – 444 104 (Maharashtra) |

E-mail: anilkumarkamble1974@gmail.com | |||

| 2. | ICAR-IIHR, Bengaluru | Dr. Carolin Rathinakumari Principal Scientist & PI, AICRP on EAAI, ICAR-Indian Institute of Horticultural Research, Hessergutta, Lake Post office, Bengaluru – 560 089 (Karnataka) |

E-mail: carolin.rathinakumari@gmail.com | |||

| 3. | ICAR-CIAE Bhopal | Dr. Sandip Gangil, Principal Scientist & Head, AEP Division, ICAR-Central Institute of Agricultural Engineering, Nabi Bagh, Berasia Road, Bhopal - 462 038 (Madhya Pradesh) |

E-mail: gangilsandip@yahoo.co.in | |||

| 4. | TNAU Coimbatore | Dr. D. Ramesh Professor & Head, Department of Renewable Energy Engineering, Tamil Nadu Agricultural University, College of Agricultural Engineering, Lawly Road, Coimbatore - 641 003 (TN) |

E-mail: rameshd@tnau.ac.in bioenergy@tnau.ac.in |

|||

| 5. | SPCW Courtallam | Dr. G. Saravanapriya Research Engineer (AICRP on EAAI), Sri Parasakthi College for Women, Courtallam - 627 802 (Tamil Nadu) |

E-mail: saravanapriya.g@gmail.com |

|||

| 6. | ICAR-NRRI Cuttack | Dr. P. C. Jena

Senior Scientist & PI, AICRP on EAAI, Department of Agricultural Engineering, ICAR-National Rice Research Institute, Cuttack – 753 006 (Odisha) |

E-mail: prakiitkgp@gmail.com | |||

| 7. | UAS Dharwad | Dr. Shubha. S Jr. Microbiologist, AICRP on EAAI, Department of Microbiology, University of Agricultural Sciences, Dharwad – 580 005 (Karnataka) |

E-mail: geetagoudar@gmail.com | |||

| 8. (i) | CCSHAU Hisar (DRET-BCT) | Dr. (Mrs) Kamla Malik Assistant Scientist & PI, AICRP on EAAI, Department of Microbiology, CCS Haryana Agricultural University, Hisar - 125 004 (Haryana) | E-mail: kamlamalik@rediffmail.com | |||

| 8. (ii) | CCSHAU Hisar (DRES) | Dr. (Mrs.) Yadvika Professor & Head, Department of Agricultural Processing & Energy, College of Basic Sciences, CCS Haryana Agricultural University, Hisar - 125 004 (Haryana) |

E-mail: yadvika6@yahoo.co.uk | |||

| 9. | PAU Ludhiana | Dr. S. S. Sooch Professor, School of Renewable Energy Engineering, Punjab Agricultural University, Ludhiana - 141 004 (Punjab) | E-mail: sssooch@pau.edu | |||

| 10. | ICAR-IARI New Delhi | Dr. Shiv Prasad Principal Scientiest & PI-AICRP on EAAI, Division of Environmental Sciences, ICAR-Indian Agricultural Research Institute, Nuclear Research Laboratory Building, Pusa, New Delhi - 110 012 | E-mail: shiv_drprasad@yahoo.co.in | |||

| 11. | CSKHPKV Palampur | Dr. D. K. Vatsa Dean, College of Agriculture, and Research Engineer, AICRP on EAAI, CSKHPKV, Palampur - 176 062 (Himachal Pradesh) | E-mail: drdkvatsa@gmail.com | |||

| 12. | GBPUA&T Pantnagar | Dr. R. N. Pateriya Professor & Research Engineer, AICRP on EAAI, Department of Farm Machinery & Power Engineering, College of Technology, GB Pant University of Agriculture & Technology, Pantnagar - 263 145 (Uttarakhand) | E-mail: tpsingh.fmp@gmail.com | |||

| 13. | UAS Raichur | Dr. Vijay Kumar Palled Research Engineer (AICRP on EAAI), College of Agricultural Engineering, University of Agricultural Sciences, Raichur - 584 101 (Karnataka) | E-mail: vs.palled@gmail.com | |||

| 14. | BAU Ranchi | Dr. Mintu Job Asstt. Professor & Research Engineer, AICRP on EAAI, College of Agril. Engineering, Birsa Agricultural University, Kanke, Ranchi – 834 006 (Jharkhand) | E-mail: mintujob@rediffmail.com | |||

| 15. | MPUAT Udaipur | Dr. N. L. Panwar Associate Professor & PI-AICRP on EAAI, Department of Renewable Energy Engineering, College of Agricultural Engineering & Technology, Maharana Pratap University of Agriculture and Technology, Udaipur - 313 001 (Rajasthan) | E-mail: nlpanwar@gmail.com | |||

| 16. | SPRERI Vallabh Vidyanagar | Dr. A. K. Dubey Director, Sardar Patel Renewable Energy Research Institute, Post Box No. 2, Vallabh Vidyanagar - 388 120 (Gujarat) | E-mail: director@spreri.org | |||

| * | ICAR-IASRI, New Delhi | Dr. Kaustav Aditya Senior Scientist, Division of Sample Surveys, ICAR-Indian Agricultural Statistics Research, Institute (IASRI), Library Avenue, PUSA, -110012, (New Delhi) | E-mail: director@spreri.org | |||

Prominent Technologies Developed

Solar PV-operated ice cream thela for street vendor

A 100 liter solar photovoltaic operated ice cream cart with a mobile refrigeration system for ice cream vendors was designed and developed to help uplifting the economic conditions of vendors by reducing their dependence on the utility grid, hence cutting off operational costs of the cart. The components were assembled on a four-wheeled cart where the three panels with a rated power of 165W each are connected in parallel as shown in Figure. A charge controller of capacity 675VA and two batteries with a rated capacity of 12V, 100Ah. Eco-friendly R600a refrigerant was used as a cooling agent. During the preliminary study under on-load conditions. It was observed that the backup period once fully charged is about 16 hours, and able to maintain average temperature of -18oC. Design patent granted on June 20, 2023, for the Manual Driven Solar Power Ice Cream Cart from the patent office, Government of India.

Co-digestion of paddy straw with Nitrogen rich agro-residues for enhancing biogas production

The co-digestion of paddy straw with Nitrogen rich agro-residues for enhancing biogas production was carried out at PAU, Ludhiana to increase the utilization of paddy straw at farmer’s field. After laboratory scale optimization of the co-digestion process of paddy straw using agro residues like green potato waste, mung residue, mint residue, sugarcane bagasse (SCB), spoiled potato waste, poultry droppings, cattle dung and bio-digested slurry, field trial was conducted with 350 kg paddy straw at farmer field as shown in Figure. Paddy straw 350 kg of co-digested with 50% cattle dung produced 289.34 l biogas/kg PS in MS biogas plant installed at village Malliana, Moga. Co-digestion of paddy straw with poultry droppings @25% resulted in the formation of 75 m3 biogas within 2 months. Proximate and chemical analysis of initial and final feed stocks showed decrease in TS, VS, TOC, cellulose, and hemicellulose content while the increase in ash, lignin and silica content. Hence, the co-digestion of agro residues with PS is a promising method for increasing biogas production from paddy straw management.

Bubbling fluidized bed gasifier for hydrogen rich syngas production from agricultural waste biomass using air/steam gasification

A bubbling fluidized bed gasifier for hydrogen rich syngas production from agricultural waste biomass using air/steam gasification as shown in Figure was designed and developed. Three agricultural residues viz. Mustard stalk (MS), Wheat stalk (WS) and Bengal gram stalk (BGS) have been selected as feed material. The bubbling fluidized bed gasifier (BFB) was designed to operate at atmospheric pressure with a capacity of 5 kg/h (24 kW). The catalytic bed (olivine) has a moderate influence on gas composition as compared to the sand bed. Air-steam gasification has resulted in significant H2 enrichment of syngas. It was found that the H2 concentration obtained was 8.78 % for air gasification, which increased to the highest value of 18.56 % at the S/B ratio of 0.5. This resulted in the highest H2 yield of almost 0.46 Nm3/kg over the 0.19 Nm3/kg obtained for air gasification. BGS also observed the highest H2 yield of 0.38 Nm3/kg for the S/B ratio of 0.5 as compared to air gasification of 0.19 Nm3/kg. WS, H2 concentration reached to maximum concertation of 7.44% for air gasification, which was enhanced to 13.27% at the S/B ratio of 0.5. The highest H2 yield obtained was 0.29 Nm3/kg for the S/B ratio the 0.5 as compared to air gasification, which was about 0.15 Nm3/kg. The payback period of the developed system was estimated as 2.7 years which is equal to 32 months, and the B/C ratio was calculated as 1.22. Net present worth (NPW) was ₹ 392275.5. The internal rate of return was 35.79%. The developed BFB gasification technology can be used for thermal applications in small industries using waste biomass materials. A Patent on Bubbling Fluidized Bed Gasifier for Hydrogen Rich Syngas from Agro-waste was also filed (2022/10900:Republic of South Africa).

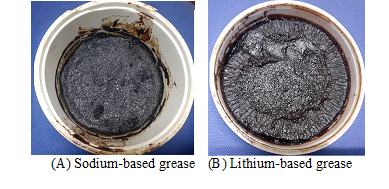

Lubricant(grease) from pine needle bio-oil

A process of grease preparation from pine needle pyrolysis oil has been developed at GBPUAT, Pantnagar centre of ACIRP on EAAI by replacing the pyrolysis oil as base oil with mineral oil and animal fat (goat) as thickener other than vegetable oil (Fig.). The produce grease has good quality, eco-friendly, biodegradable, non-toxic in nature and low cost. According to the TGA and DTG analysis of grease samples, grease of Na-based with mineral oil (sample A) has the maximum thermal degradation as compared to grease of Na-base with bio-oil (sample B) and grease of Li-based with bio-oil. Cone penetration and copper corrosion values were the identical for all samples, demonstrating its liquid consistency and metal-protecting nature. Fe, Cu, and Pd were identified in slightly higher concentrations in grease samples. Ca, Mg, Zn, and P were discovered in extremely little amounts in the grease samples. The ferrographical study revealed relatively few wears and contaminations in grease samples, showing that the grease behaved in good quality. This grease could be suitable for applications in areas of normal working temperatures such as roll bearings, gears including other application. The biodegradability of these pyrolysis based greases allows the wasted grease to degrade naturally and cause no damage to the environment in the process.

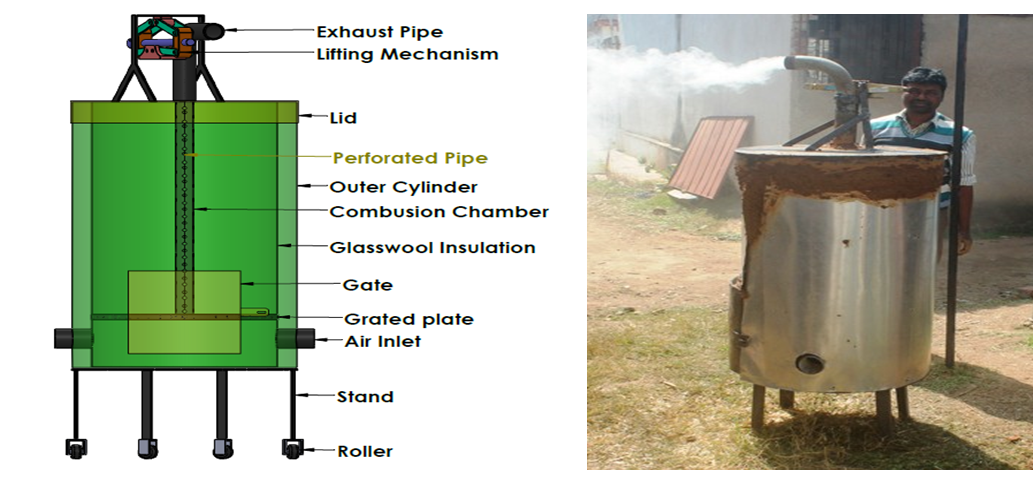

Small scale portable biochar kiln for biochar production from agricultural waste residue

The BAU, Ranchi centre of AICRP on EAAI developed a small scale portable biochar kiln for biochar production utilizing agricultural waste residues. The updraft portable Biochar kiln consisted of a kiln unit of cylindrical shape and circular cross section, a gated opening for the burning bed and perforated pipes for the transmission of exhaust gases. Schematic view, detailed view and developed small scale portable biochar kiln is shown in the Fig. A, and Fig. B, respectively. The Kiln was tested utilizing wheat straw and groundnut husk. About 3.5 kg of wheat straw and 4.2 kg of groundnut shell was fed separately and packed by opening the lid into the combustion chamber, the biomass was held in between the grated plate with a layer of firing coal. Burning was made by opening the ash chamber gate. The recorded temperature during the process of pyrolysis were 312C and 320C for wheat straw and ground nut shell respectively. Actual time required for complete conversion for wheat straw was 92 minutes and that of groundnut shell was 123 minutes. Average Biochar yield in case of Wheat and Ground nut shell was found out to be 28.85% and 31.42%, respectively. Carbon content of groundnut Shell was found to be 71.6% and that of Wheat straw was 62.94 %. Calorific value as well as Energy density were found more for chars obtained from groundnut shell.

Solar Insect Trap

A solar insect trap consisting of a solar panel, lead acid battery, charge controller, relay circuit and LED light was evaluated in the field. The insect trap could run from evening 5.30 PM to Morning 8.30 AM (15 hours). The power generated from the solar panel ranged from 2.6 to 9.84 W and the efficiency of solar panels ranged from 12.3 to 14.1 %. The maximum efficiency (14.1%) was observed when the ambient temperature was around 25°C and solar intensity was 285 W/m2. 25 to 50% of Pink Boll Worm insects were trapped by the insect trap depending upon the day of occurrence of the pest which is a predominant insect in cotton crop that affects the yield significantly which shows a positive inclination towards the application of solar insect trap for eco-friendly protection of cotton crop thus reducing the utilization of chemicals/pesticides for spraying in cotton. The entomological data indicated that this trap could be used for trapping insects effectively and thus an eco-friendly tool for the protection of crops. This trap can be used for trapping insects from an area of 0.5 ha. Two manufacturers have been identified for the fabrication of solar operated insect traps. A total of 5 units of solar operated insect traps have been fabricated and demonstrated in farmer’s fields.

Solar operated Leaf Nipping Machine

The solar operated leaf nipping machine was developed and evaluated in Pigeonpea crop at Main Agricultural Research Station (MARS), UAS Raichur and demonstrated in Pigeonpea crop at Farmer’s field in Dinni Village of Raichur district. The theoretical and effective field capacity of the machine was found to be 1.2 and 0.9 ha/h with a field efficiency of 75% at an operator walking speed of 2.8 kmph against the effective field capacity of 0.75 ha/h with manual nipping. The developed machine saves about 20% time and reduces the drudgery of the operator.

Training program on the application of renewable energy in agriculture under the SCSP component of AICRP on EAAI

Training program on Application of Renewable Energy in Agriculture were organised by the copperating centre of AICRP on EAAI; Dr. PDKV, Akola, TNAU, Coimbatore, NRRI, Cuttack, MPUAT, Udaipur and GBPUA&T, Pantnagar.